Gear Motors Selection Guide: Inspection, Types, Applications

The majority of industrial machines require some form of mechanical energy in order for them to function. Here is where the humble electric gear motor proves itself invaluable. Two key measurements of any motor are speed and torque value.

‘Off the shelf’ conventional motors typically generate high speeds, but low torque. Many industrial applications, however, require high torque at reduced speeds. A gear motor solves this problem for many applications by delivering the right amount of speed and torque.

Related Links

- https://rentry.co/23gyf

- https://sco.lt/9BGRYu

- https://gab.com/islproductsny/posts/111725945478733726

- https://xokki.com/energy-efficiency-and-sustainability-in-dc-gear-motor-design/

- https://thehealthvinegar.com/page/business-services/energy-efficiency-and-sustainability-in-dc-gear-motor-design

- https://wakelet.com/wake/19E4eLfd7s1_6nIlPcGIE

- https://newsocialbookmarkingsite.com/story/energy-efficiency-and-sustainability-in-dc-gear-motor-design

- https://ikeepbookmarks.net/page/business-services/energy-efficiency-and-sustainability-in-dc-gear-motor-design

- https://islproductsny.medium.com/energy-efficiency-and-sustainability-in-dc-gear-motor-design-f228de044471

- https://sites.google.com/view/isl-products/blog-page/energy-efficiency-and-sustainability-in-dc-gear-motor-design

- https://islproductsinternational.hashnode.dev/energy-efficiency-and-sustainability-in-dc-gear-motor-design

- https://penzu.com/p/c27bbe77d4600b05

- https://islproductsny.bcz.com/2024/01/22/energy-efficiency-and-sustainability-in-dc-gear-motor-design/

Closer inspection

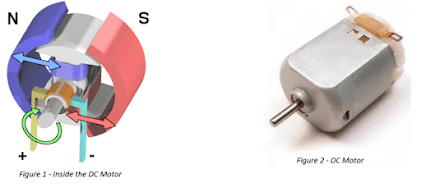

A gear motor reduces power by way of its gearing, transferring speed into torque power. Whilst gear motors conventionally feature metal housings hybrid motors have now emerged, which offer increased durability and increased efficiency. Hybrid motors accommodate their gearing mechanism in a plastic housing, whilst the gears themselves are made of metal. Such a setup has the added advantage of reducing noise.

The humble gear motor has found its home in countless applications. Domestic appliances such as; portable blenders, electric dental hygiene devices, grooming devices, and vacuum cleaners are just a few of the countless products that are powered by gear motors. And whilst we use such applications on a daily basis, few of us realize how lost we’d be without them.

Forms of Gear Motor:

Categorized by their reducer, gear motors offer high versatility and are available in a wide range of different designs, including;

Helical gear motors

Planetary gear motor

Worm gear motor

Wave gear motor

Spur gear motor

Such gear motor designs are widely used in industries / sectors such as:

Engineering

Mining

Healthcare

Automobile accessories

Office automation

Commercial printing

Industries are constantly evolving, and both systems and applications require frequent updating. As a result, the scope of the gear motors is also continuously being widened, with consistent effort being made to improve performance and functionality. This forward momentum has led to the creation and adoption of low-weight, highly compact motors that do not compromise on performance.

Selecting the right motor

There are a number of parameters to consider become making a decision about which motor may best suit the needs of your application:

A phase of design evaluation in which the product development requirements, design factors, functionality, and design are thoroughly reviewed.

Gear ratio, torque, rotational mass, service intervals, load, and data analysis are all determined by design calculations.

After completing the initial design evaluation to define the applicational variables, you can then use this data to determine which motor or gear motor will best match your application.

Once you have chosen the most appropriate gear motor, connect with ISL Products. ISL Products design and manufacture a large range of exceptionally high quality gear motors.

ISL Products are renowned for their electro-mechanical solutions and have been an industry leader for over forty years. For superior performance, durability, and impeccable customer experience, choose ISL Products.

.jpg)

Comments

Post a Comment