6 Benefits of Using a Brushless DC Motor

The brushless DC motor has gained immense popularity in recent times and has become the go-to choice for various industries. With their advanced technology, these motors offer several benefits that make them stand out from traditional DC motors. In this post, we'll discuss six benefits of using brushless DC motors. Let’s get started.

Related Links:

- https://bookmarkrush.com/story/experience-clear-sound-with-piezo-transducers/

- https://www.tumblr.com/islproductsny/733303733638791168/piezo-transducers-isl-products-international?source=share

- https://gab.com/islproductsny/posts/111345477704190912

- https://expressafrica.et/post/225730_isl-products-international-your-destination-for-brushless-dc-motors-explore-adva.html

- http://ttlink.com/bookmark/b95b64aa-4cc8-4da6-9a76-6f97b6a41499

- https://sco.lt/5T7rbk

- https://www.realbookmarking.com/story/efficient-planetary-gear-motors-for-diverse-applications

- https://wakelet.com/wake/LC7CE_Xa9V-Hfk8xwRbQf

- https://diigo.com/0ughk1

- https://glose.com/activity/655b43bc6467cc530835520e

High Efficiency

Brushless DC motors are known for their outstanding efficiency. Unlike brushed motors, BLDC motors don’t have brushes, which reduces energy loss and minimizes friction.

This streamlined design results in higher overall efficiency, translating into energy savings and reduced operating costs. The high efficiency of brushless DC motors delivers optimal performance and reduces the environmental impact.

Long Lifespan

Another significant advantage of brushless DC motors is their extended lifespan. The absence of brushes eliminates the wear and tear associated with traditional brushed motors. With fewer mechanical parts subject to friction and contact, brushless DC motors exhibit exceptional durability and longevity.

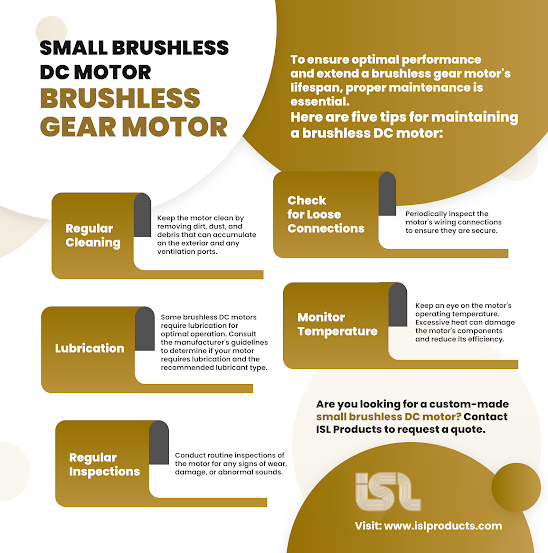

Low Maintenance

Brushless DC motors require minimal maintenance compared to their brushed counterparts. Without brushes to replace or commutators to clean, the maintenance tasks associated with brushless DC motors are significantly reduced. This leads to less downtime, increased productivity, and lower maintenance costs.

High Torque-to-Weight Ratio

A BLDC motor offers an impressive torque-to-weight ratio. This means it can deliver high torque levels relative to its size and weight. The design of brushless DC motors allows for efficient power delivery and improved torque output. This characteristic makes them perfect for applications such as robotics, aerospace, and automotive systems.

Precise Speed Control

Brushless DC motors excel in precise speed control. Their digital control systems and advanced feedback mechanisms like encoders or Hall effect sensors enable accurate and responsive speed regulation.

This precise control allows for smooth and controlled motor operation. This makes these motors suitable for applications like robotics and CNC machines that require precise speed control.

Low Noise

Brushless DC motors operate with remarkably low noise levels. The absence of brushes eliminates the sparking and mechanical noise often associated with brushed motors.

The smooth operation of brushless DC motors, combined with advanced electronic commutation, ensures quiet performance. This quiet operation is particularly valuable in applications where noise reduction is crucial like medical devices and audio equipment.

Whether it's improving energy efficiency, optimizing performance, or enhancing user experience, a brushless gear motor delivers exceptional results. ISL Products is a top manufacturer of Brushless DC motors. Having been in the industry for decades, we are better positioned to manufacture a BLDC motor that meets your specific needs.

Our motors can be customized based on parameters such as torque, current, and voltage. If you need a brushless DC motor, contact us today to request a quote.

.jpg)

Comments

Post a Comment