What distinguishes brushless dc motors from standard brushed dc motors?

What distinguishes brushless dc motors from standard brushed dc motors?

A large number of electrical and mechanical applications rely on the implementation of motors. Firstly, it’s important to appreciate that DC motors offer more precise control, compared to AC motors. Also, DC motors are much more suitable for applications that require the active management of speed, positioning and torque.

There are two variations of commonly used DC motors: brushed motors and brushless motors (also referred to as ‘BLDC’ motors). Brushed motors, as their name implies, are motors that feature brushes to commutate the power within the motor and make them operate. Brushless DC motors, on the other hand, replace mechanical commutation with electronic functioning.

The use of both brushless and brushed DC motors is common across multiple industries. In simple terms they function on the principle of magnetic attraction and repulsion. Selecting between the two depends on the specific requirements of an application.

The Brushed DC Motor

DC motors feature coils that create an opposing magnetic field to the stationary stator permanent magnets. These coils are generally arranged around an iron core and drive the motor rotor. The stator features stationary permanent magnets which almost encase the rotor. The brushes make contact with the rotor and energize the windings, inducing the needed magnetic field to begin rotating.

The brushes used in standard DC motors act as a conductor that carries current to the moving components of the motor. The operational speed of a DC motor can be changed by adjusting the voltage that the motor will see.

However, brushes in the motor create friction. This friction results in the brushes wearing down after extended use. Due to this fact they will eventually start functioning very inefficiently or not at all. Nevertheless, brushed motors have been in use for nearly a century now in a huge variety of applications.

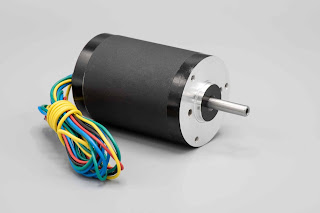

As their name suggests, Brushless DC motors do not feature brushes. While brushless motors operate on the same principles of magnetic repulsion and attraction, their construction is, in a way, almost opposite that of brushed Motors. Brushless DC motors feature a permanent magnet rotor, with no coils being wound around it. Instead, the coils are locked in place on the stator and this is the portion being energized, not the rotor. Due to this arrangement, there is no need for brushes and mechanical commutators.

One of the main features of brushless DC Motors is that they offer high torque and power, with high degrees of control. Due to the absence of brushes, the amount of friction and consequent heat created is minimal. This is the reason why brushless motors offer a much longer serviceable lifespan in comparison to brushed motors.

In conclusion, it is correct to say that brushless motors offer a more comprehensive set of features in comparison to brushed motors. The table below makes a brief comparison:

- https://www.evernote.com/shard/s486/sh/cca26824-d581-0c9c-b7a9-35ce1765ce63/Wn45pqJ6TPIA3kUOGut_3JHHlt1YGfFA1-6AqQrLUPotG2hMiw4CYENuXQ

- https://tempaste.com/bvkGsIJAaXl

- https://diigo.com/0usor4

- https://profilebook.mn.co/posts/47361991

- https://islproductsny.medium.com/4-innovations-in-brushless-dc-motor-technology-whats-next-5498b5c40d17

- https://isl-products.blogspot.com/2023/12/4-innovations-in-brushless-dc-motor.html

- https://www.tumblr.com/islproductsny/737389658105872384/4-innovations-in-brushless-dc-motor-technology?source=share

- https://www.sutori.com/en/story/untitled--dyaYBux39tHnhGUR61HiMpHp

- https://wakelet.com/wake/Bm9NDxfa1zNcqY13UcoTH

- https://acertdglobalplatform.mn.co/posts/47659610

.jpg)

Comments

Post a Comment