Why Are Brushless Motors So Efficient?

In order to fully understand the functioning of a brushless motor, it may help to first examine a brushed motor. Most brushed motors are constructed with permanent magnets and an electromagnetic armature rotating within the permanent magnets. When supplied with direct current the electromagnets induce a magnetic field, which as a result, rotates the armature.

With brushed motors, the brushes continuously alter the polarity of the armature causing rotation from the magnetic attraction and repulsion forces. The fundamental principles of a brushed DC motor and a brushless DC motor are very similar.

Similar to a brushed motor, a brushless DC motor contains the two basic components - the rotor and the stator. But in the case of a brushless DC motor, the electromagnet portion is stationary, hence the name stator, whilst the permanent magnets are located on the rotor.

Brushless DC motors (BLDC motors) when supplied with power also alternate the polarity but this time of the stationary stator portion, causing the permanent magnet rotor to rotate. This power transmission is called electrical commutation and does away with the need for brushes used in mechanical commutation.

There are essentially two main forms of brushless motors - an outer rotor motor, and an inner rotor motor. Both variations function on the same principles, it’s the form and design that differentiates them both.

Inner rotor motor

With the inner rotor design, the rotor is situated in the centre of the motor, with a stator winding that encompasses the rotor. Because the rotor is located in the centre, it is smaller and has lower inertia which is good for quick acceleration.

Outer rotor motor

With the outer router design, the winding is located in the centre of the motor, with a rotor that surrounds it. This increases the moment arm of the rotor which results in increased inertia and power output.

Here are seven benefits that make brushless dc motors an attractive solution:

- The loss of energy in the process of translating electrical power to mechanical power is greatly reduced due to the absence of brushes, resulting in reduced friction.

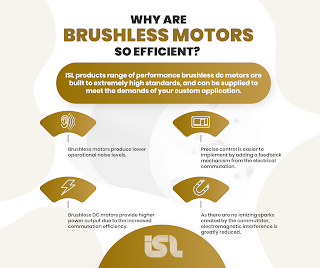

- They produce lower operational noise levels.

- Precise control is easier to implement by adding a feedback mechanism from the electrical commutation.

- In the case of inner rotor brushless DC motors, low rotor inertia allows them to accelerate and decelerate very easily.

- Brushless DC motors provide higher power output due to the increased commutation efficiency.

- Due to the absence of brushes they have a longer serviceable life expectancy.

- As there are no ionizing sparks created by the commutator, electromagnetic interference is greatly reduced.

- Brushless motors tend to remain cooler than their brushed motor counterparts because of the reduced friction.

ISL Products have provided highly specialized component solutions, tailor-made for a wide range of applications.They offer integrated expert assistance, along with global logistical support.

ISL products range of performance brushless dc motors are built to extremely high standards, and can be supplied to meet the demands of your custom application.

Related Links:

- https://trendhour.com/4-innovations-in-brushless-dc-motor-technology-whats-next/

- https://bookmarkrush.com/story/4-innovations-in-brushless-dc-motor-technology-whats-next/

- https://bookmarkrocket.com/story/4-innovations-in-brushless-dc-motor-technology-whats-next/

- https://flip.it/I9iaQH

- https://www.pickmemo.com/post/455996_4-innovations-in-brushless-dc-motor-technology-what-039-s-next-discover-the-futu.html

- https://www.mbookmarking.com/story/4-innovations-in-brushless-dc-motor-technology-what-s-next

- https://gab.com/islproductsny/posts/111606765511027762

- https://sco.lt/5LSrsu

- https://pudya.com/4-innovations-in-brushless-dc-motor-technology-whats-next/

- https://submission.wtguru.com/2023/12/21/4-innovations-in-brushless-dc-motor-technology-whats-next/

.jpg)

Comments

Post a Comment