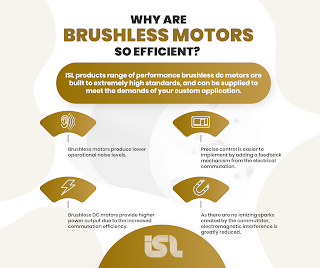

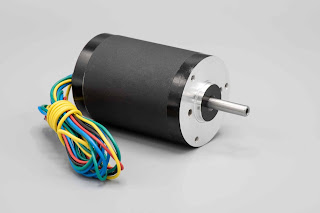

High Performance BLDC Motor Solutions

ISL Products International Ltd provides value-added, small brushless DC motors & brushless gear motors . Our BLDC motors offer reliable speed & high efficiency for precision applications. Related Sites: https://expressafrica.et/post/233213_stepper-motors-in-cnc-machines-precision-and-control-discover-the-intricate-worl.html https://www.freebookmarkingsubmission.net/page/other/stepper-motors-in-cnc-machines-precision-and-control https://freesubmission.xyz/page/other/stepper-motors-in-cnc-machines-precision-and-control https://gab.com/islproductsny/posts/111566150303998793 https://diigo.com/0uq7el https://www.pearltrees.com/islproductsny2/item563456269 https://kisza.com/stepper-motors-in-cnc-machines-precision-and-control-2/ https://oodare.com/post/254018_stepper-motors-in-cnc-machines-precision-and-control-discover-the-intricate-worl.html https://www.buzzbii.com/post/873279_stepper-motors-in-cnc-machines-precision-and-control-discover-the-intricate-worl.html https...